Microsoft Dynamics 365

Supply Chain Management

Modern companies need a logistics and supply network that is reliable and resilient to shocks. In order to run a tight ship,

you need end-to-end visibility of the supply chain, reduce asset downtime, and have data that is easily

available to help you accurately predict demand and ensure timely delivery of products.

Dynamics 365 Supply Chain Management empowers businesses to automate and obtain a complete integrated

overview of inventory, warehouse, manufacturing, service, and logistics all at one place,

thus helping in better management.

Features

01

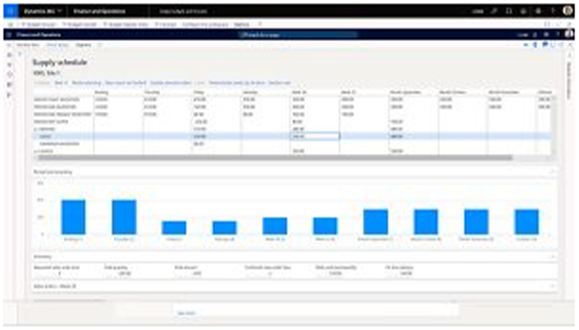

Automate your supply chain operations

- Work with a complete supply chain perspective across different geographic locations and time zones, integrating purchasing and sales with the management of logistics, stock, production, warehouses, and transport.

- Optimize purchasing processes by using a single application from procurement to payment, with which you can manage contracts, incorporate vendors, monitor delivery performance, and collaborate with external suppliers.

- Improve orders and deliveries to customers with more accurate estimates taking into account availability of goods and capacity constraints between different companies, locations, and warehouses.

- Optimize order processing and reduce costs by syncing logistics between different locations, warehouses, and modes of transport.

- Expedite product delivery by automating the flow of information and materials between resources and locations.

- Boost quality and customer satisfaction with built-in QA capabilities, Quickly identify and resolve problems by using predictive insights in real time.

02

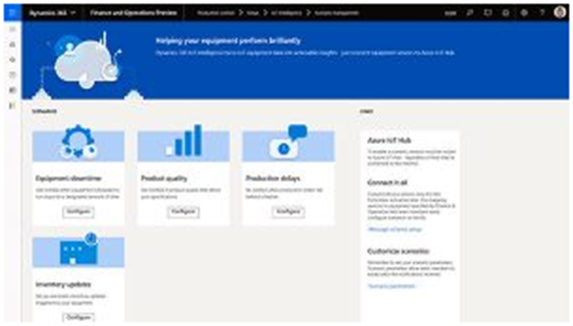

Optimize production performance with IoT Intelligence

- Make effective decisions with a real-time view of all productionactivies and stock. Proactively manage plant and machinery operations to improve uptime, performance, and quality.

- Boost the efficiency of your resources, processes, and people by using AI, machine learning and mixed reality to proactively predict and solve problems.

- Perform predictive maintenance before to avoid serious errors that could avoid costly downtime for critical equipment.

03

Innovate with smart manufacturing operations

- Build a connected shop floor and manage processes and operations effectively with IoT, AI, machine learning, and mixed reality.

- Simplify resource management for any workload with a solution that helps you control and manage your resources, from people to equipment to tools and machinery.

- Create suitable processes for any type of manufacturing discrete, lean, project-based, process-based or mixed that satisfy all your needs with a single solution.

- Create a mixed mode manufacturing environment that supports all strategies such as make-to-stock, make-to-order, configure-to-order and design-to-order.